- +86-510-87588788

- m13601537536@163.com

- Jiangsu Huacheng Baoyi Machinery Co., Ltd.

1. Problems in the separation of heavy aromatic at present

Heavy aromatic is the industrial product of coal gasification. It is a kind of crude gas product with complex components produced by coal pyrolysis in the process of coal gasification. Heavy aromatic is widely used in chemical industry, the separated products can be used to produce many kinds of chemical products. Gravity sedimentation method was used to separate heavy aromatic, but there were many problems such as unstable operation, difficult to clean up the dust and high water content.

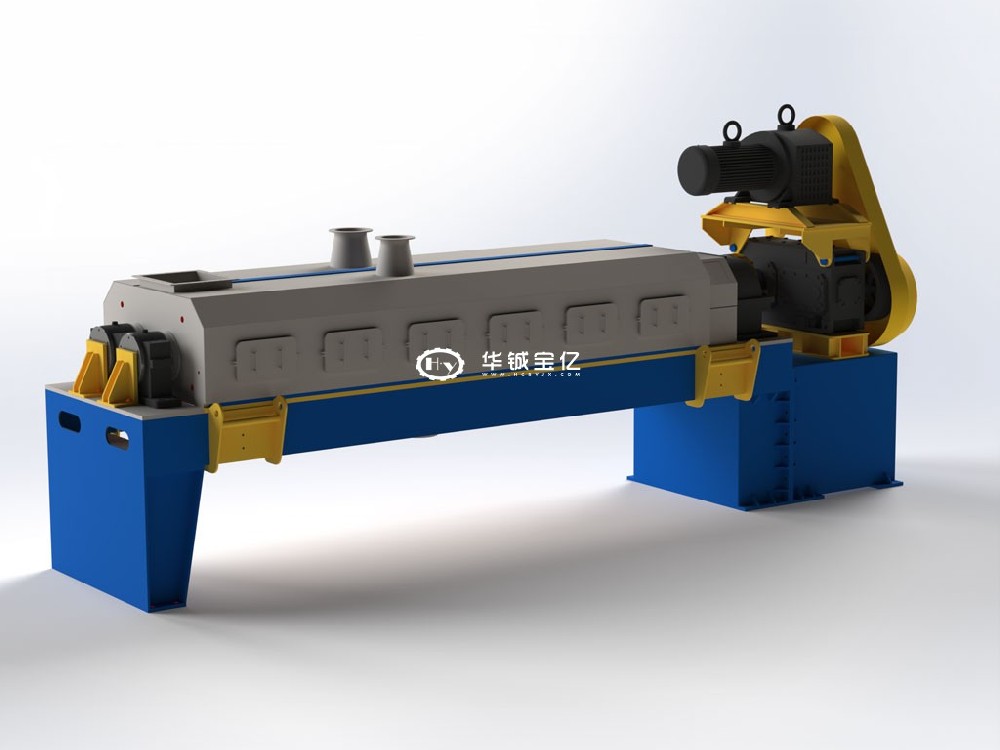

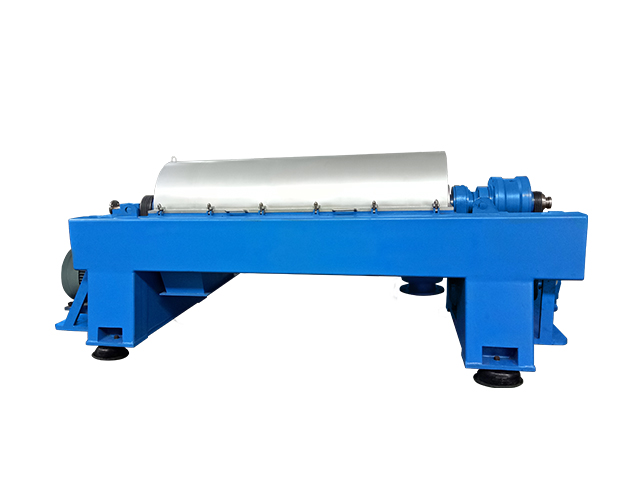

2. Principle of three-phase centrifuge in heavy aromatic separation

The heavy aromatic suspension will be fed into the drum of the centrifuge from the feed inlet. The workers should take protective measures to avoid the heavy aromatic suspension splashing on the clothes. After that, the drum will rotate in high speed, the suspension will be divided into water, slag and heavy aromatic because of the different density.

3. Characteristics of three-phase centrifuge

3.1 Screw structure design

The feed inlet is designed with hydrodynamics and double S shape to avoid material accumulation. At the same time, the screw is designed with variable pitch and blade opening, which can speed up the separation efficiency.

3.2 Anti-wear design of drum

The treatment of slag is the key point of heavy aromatic separation, if the slag is not treated well, it will affect the normal operation of the centrifuge, and cause wear and tear. The three-phase centrifuge is designed with a saddle shaped discharge outlet for smooth slag discharge and easy to clean. At the same time, the slag discharge outlet can be replaced easily, which also reduces the wear of the centrifuge.

3.3 Large aspect ratio

The design of large aspect ratio extends the time of the heavy aromatic suspension staying in the drum, and ensure that each component can be well separated.

4. Advantages of three-phase centrifuge in heavy aromatic separation

4.1 Improvement of environment protection

When the three-phase centrifuge is used to separate the heavy aromatic suspension, all the work is carried out in the machine and controlled by the machine. Compared with the traditional heavy aromatic separation method, it has the advantages of small area coverage, less waste discharge.

4.2 Improvement of separation effect

Compared with the traditional separation process, the three-phase centrifuge has the advantages of simple operation,high separation efficiency and good separation effect, it can also reduce the cost of post-treatment.

4.3 Labor saving

Compared with the traditional separation process, the three-phase centrifuge is automatic. It only needs a few workers, which greatly reduces the human cost of the enterprise.